- Client First

- Effective Synergy

- On Time Delivery

- Strong Expertise

- Feedback Based

- Results Focused

We, Advance Engineering Co. appreciate deeply your encouragement and opinions.

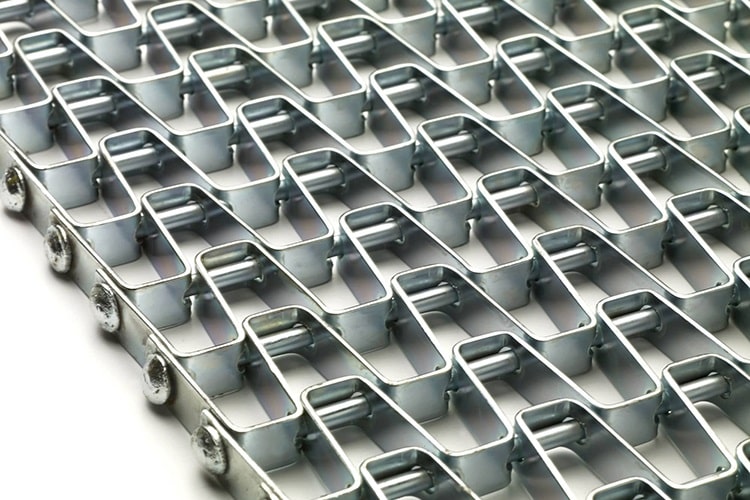

We manufacturers, exporter and designed, manufactured and selled many kinds industrial belts by precision machines. We Advance Engineering Co. is a famous industries in Faridabad wire mesh conveyor belt manufacturer, Exporter as well as lehr belt, eyelink belts, enrober wire belt and honeycomb belt in India. Our Metal are reliable and outstandingly superior products, manufactured under our strict process of highly advanced quality care system and thorough quality examination procedures.

If you are looking for the Exporter, manufacturers of conveyor belt, lehr belt, eyelink belts, enrober wire belt and honeycomb belt in India? please contact us online to know know about the price or consult for wire mesh belt , lehr, eyelink, enrober and honeycomb belt in Haryana. Our main focus is to provide 100% satisfaction and commitment to innovation and technology and promise to improve the productivity of your company. We also hope your eternal safety and prosperity.

We are the leading wire mesh belt manufactures | Our aim is to be a leader in wire mesh belt manufacturers segment. At the helm of an Industry, working towards continuous improvement in technology and quality, being completely responsive to the customer’s requirements and continuous learning will be the way of life. Being responsive to the society we live in. Our main vision is to export the high quality wire mesh conveyor belt.

Our company main philosophy is to build the best wire mesh belt and they should be built and offer them at competitive prices for the broadest market. Our in-house design, manufacturing & testing facilities are a testimony to our commitment towards customers’ success. With this we focus on controlling costs, ensuring component availability and on time deliveries. As we are leading wire mesh belt manufacturers then our main mission is to deliver best of our product.

Advance Engineering is committed to become the high-quality wire mesh belt manufacturers in India. We are leading Exporter of wire mesh belt. Wire mesh belt are mainly used transport products in a straight line or through changes in elevation or direction in multiple industries such as Healthcare, Beverage, food, Pharma, Coal, Grain and many more. There are multiple types of material used in manufacture wire mesh belt, but we manufacturers only SS wire mesh belt.

Advance Engineering is the leading wire mesh conveyor belt manufacturers in India with more than 20 years of experience in the same field. We make supreme quality and we never compromise with the quality which is set by the industry. Our superior quality wire mesh belt required low maintenance and highly demanded in the market.

We manufactured Wire mesh belt conveyor for Pharma Industries, Shrink packaging Industries, Tyre Industries, Salt Industries, Food Industries, Shot blasting machine, Biscuit Industries, Noodles Industries, Plywood Industry, Namkeen Industries, Chapati Making machine, chocolate Industry and Pizza Ovens.

Advanced Engineering use modern technology to manufacturer bulk wire mesh belt to fulfill the customer and market requirement. Before delivering the product we always double check all the safety parameters to ensure permanent flawless and supply best to customer. We also have a team of technical and professional engineers. Our Engineer uses latest resources to deliver the best wire mesh conveyor belt. We are committed to fulfill our user requirement with the best as we are topmost Wire mesh conveyor belt manufacturers in India.

Our Products

The offered metal conveyor belt for glass annealing lehr is used for the manufacturers of packaging, decorative, ovenware and possible other types of glasses.

Compound Balanced Belts are used as baking bands. These belts are also employed for unstable items that require very flat surfaces and product support. We manufacture

Gratex Belts are used with conveyors handling small parts and heavy loads. It is similar to balanced belting but its spirals are more closely wound with straight rod

Chain Driven Belts have really made considerable marks in the market. Chain drive or chain driver belt is also chosen for having longer life. In this belt roller chains

The honeycomb belts are constructed from cross rods and a flat metal strip. At the sides of the belt the cross rods have a welded ring (welded edges). In a number of dimensions

Enrober Belt is a special type of conveyor belt that is used for food grade to avoid any and every kind of contamination in food products. It is made up of stainless steel

If you’re looking for a leading manufacturer of Wire Mesh Conveyor Belts, then look no further. We are proud to be the leading provider of this innovative product, and we take great pride in delivering quality and value to our customers for more than two decades. Our website is full of information about our Wire Mesh Conveyor Belts, and we also offer a wide range of products to meet your specific needs like Metal Conveyor Belt, Wire Metal Conveyor Belt, Metal Belt Manufacturer, Metal Wire Conveyor Belt, etc. Our team is knowledgeable and experienced, and we’re always willing to answer any questions you may have. So if you need Wire Mesh Conveyor Belts, look no further than us. We are the leading manufacturer in this field, and we guarantee quality and satisfaction with every product.

Our website features detailed product information, including images and technical specifications, so you can make an informed decision about which wire mesh conveyor belt is right for you. We also have a helpful customer service team who can answer any questions you have about our products. On top of that, we offer competitive prices and fast delivery times, so you can get your required product as soon as possible. You get the best wire mesh conveyor belt at a great price. Check out our website today and see what we have to offer. We look forward to serving you soon!

It is important for manufacturers of metal conveyor belts to have access to high-quality plant and machinery, as well as testing instruments, in order to produce belts that meet the necessary standards and specifications. We have a team of experienced mechanical engineers, supervisors, and other staff which is important in ensuring that the manufacturing process is efficient and produces consistent results.

In addition to producing high-quality products, it is important to also provide good customer service and support. This can include answering customer questions, providing technical assistance, and addressing any issues or concerns that may arise. Providing timely and reliable service can help to build trust and loyalty with your customers, and can help to ensure their satisfaction with your products and services.

Please be informed we manufacture

FAQ

Ans: A wire mesh conveyer belt is defined as the continuous strip that is used in various factors for the transportation of objects through it or in producing different types of goods in a factory precisely.

Wire mesh conveyor belt can withstand various working temperatures from -50°C to 1200°C and are made of different metal alloys. The open mesh of these belts is one of their exceptional qualities. They are therefore perfect for different processes in factory-like drying or cooling where it is required for products to be exposed.

It also reduces dust and residue accumulation, and cleaning these belts takes less time; maintenance expenses also tend to be lower.

The custom-engineered, standard-component wire mesh belt conveyor is made to integrate with existing conveyor systems. Wire mesh belt is used for various applications, including metalworking, food processing, and medical room. The open belt design of the conveyor allows for quick and thorough cleaning. The wire mesh belt is impervious to chemical interaction because there are no belt fibers or plastic abrasion particles to create contamination; the conveyor is ideal for clean rooms and applications involving food, pharmaceuticals, and medical equipment. The wire mesh belt’s curved supporting surface allows for only minimal product contact, making it ideal for handling numerous food and medicinal goods.

Due to their adaptability and application, wire mesh conveyor systems are frequently employed in various industries, primarily manufacturing and logistics. Roller conveyors are also helpful in different industries, including food handling & packaging, Logistics, Steel-making, Management of baggage, Production, design, and more.

We manufactured Wire mesh conveyor belt for Pharma Industries, Shrink packaging Industries, Tyre Industries, Salt Industries, Food Industries, Shot blasting machine, Biscuit Industries, Noodles Industries, Plywood Industry, Namkeen Industries, Chapati Making machine, chocolate Industry and Pizza Ovens.

Since the metals we employ are dependable, top-notch, and long-lasting, Wirebelt.co.in is the best wire mesh conveyor belt manufacturer in India. We use a strict manufacturing process that includes a cutting-edge quality control system and in-depth quality inspection methods that our skilled specialists verify. Their conveyor belt is produced with great care, and our qualified experts inspect the quality. Our devotion to innovation and technology, along with our primary focus on your happiness, promises to increase your company’s productivity. We also pray for your continued safety and well-being.

Training

We are not only known as wire mesh belt manufacturers but our all levels of staff, including operators and maintenance engineers, can receive training that includes a detailed introduction to the general concepts governing the equipment’s design and goals.

Scheduled Maintenance Service Agreements

To keep the equipment in top working order, wire belt conveyors have offered a wide variety of planned maintenance service contracts that include frequent visits by one of our team to keep a proper check of equipment.

Safety requirements and quality evaluation

The manufacturing and testing of all equipment ensure that it complies with all health and safety regulations according to the standard of quality assurance.

Conveyor belts are often formed of five different materials: thermoplastics, metal, rubber, fabric, and leather. The fabrics are cotton or canvas, and the metals are carbon and stainless steel. Rubber composite is most used because it makes it more adaptable, durable, smooth, and seamless.

Other belt materials, including cloth, steel, polyester, or fiberglass, are also used to boost strength. In reality, many flat belts are made of mainly core material. These belts are a component of numerous conveyor types, such as trough, inclined, horizontal, food-grade, and overhead conveyors; however, they are not utilized by the chain, pneumatic, or screw conveyors.

Social Chat is free, download and try it now here!